Precision Machining for Medical Device Components

Built for healing. Machined for life-critical performance.

In medical device manufacturing, lives depend on precision. That’s why leading OEMs and suppliers trust Criterion Precision Machining to produce small, complex parts that meet the highest quality and regulatory standards.

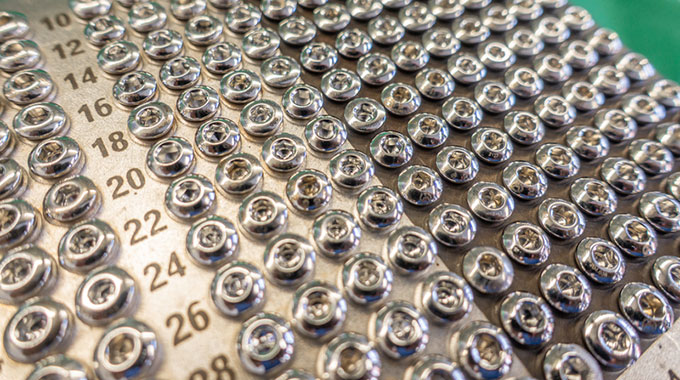

We specialize in tight-tolerance components used in surgical tools, implantable devices, diagnostic systems, and more. Whether you're scaling a new innovation or maintaining legacy production, Criterion delivers the consistency, traceability, and cleanliness your products demand.

Typical Medical Device Components Include:

Surgical tools and instruments

Implantable device housings

Endoscopic and robotic surgical parts

Material Selection for Medical Device Components: Insights from Criterion

Material selection is one of the most critical decisions in medical device manufacturing. The right material can ensure safety, reliability, and functionality, while the wrong choice can compromise the device’s performance and longevity. We understand that every medical device application comes with unique challenges, and selecting the appropriate material is the foundation of a successful project.

The Role of Precision Machining in Medical Device Manufacturing

From surgical instruments to life-saving implants, the components used in medical devices must meet rigorous standards to ensure safety, reliability, and functionality. Behind the scenes of this high-stakes industry lies precision machining, a manufacturing process that enables the creation of intricate and highly accurate parts essential for modern healthcare.